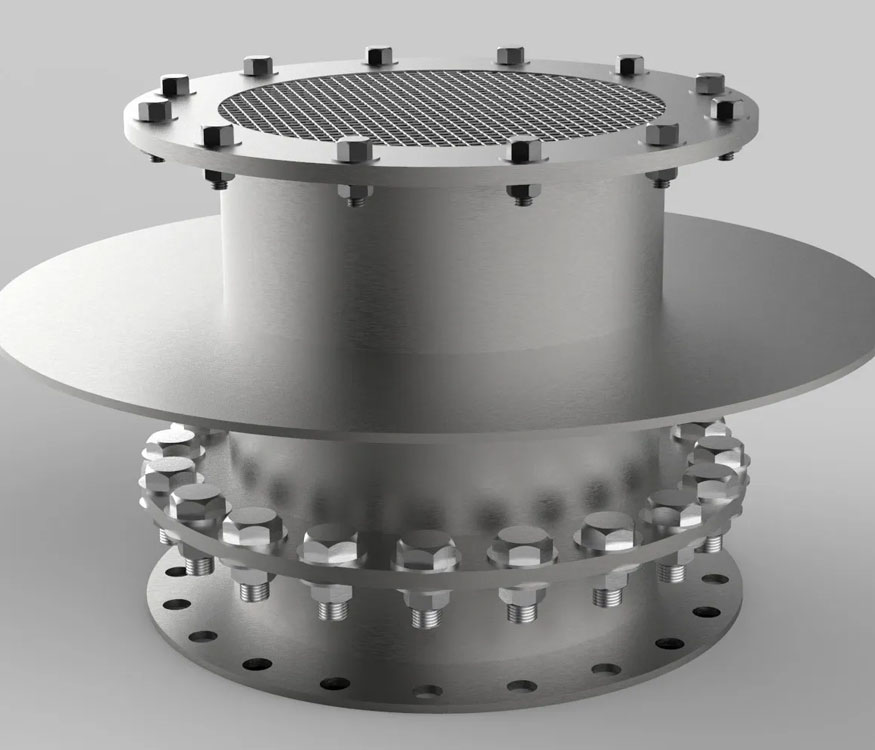

An anti-vortex plate is designed to prevent the formation of vortices in fluid systems, particularly in tanks, reservoirs, or pumps. By improving flow dynamics, it enhances the efficiency of liquid intake and reduces the risk of air entering the pump, which can cause cavitation or operational failures.

These plates help maintain smooth and uniform flow, minimizing the risk of turbulence that could disrupt system performance. Anti-vortex plates are typically made of durable materials like stainless steel or plastic and are crucial in industrial and agricultural systems requiring reliable liquid transfer without air entrapment or flow disruption.

Anti vortex plates enhance fluid flow by preventing vortex formation in tanks or pumps, improving efficiency, reducing air entrapment, and ensuring reliable liquid transfer in industrial and agricultural applications.

The anti-vortex plate’s primary function is to prevent vortex formation, improving the flow stability in pumps or tanks. This avoids air intake, ensuring smoother operations and protecting system components from cavitation damage and inefficient performance.

By stabilizing the fluid flow, the anti-vortex plate reduces turbulence, leading to improved efficiency. This feature reduces the likelihood of operational failures, ensuring consistent liquid transfer and more reliable pump performance over time, particularly in critical applications.

Constructed from corrosion-resistant materials like stainless steel or plastic, the anti-vortex plate is designed for long-term use. It is engineered to withstand harsh environments, making it ideal for various industrial or agricultural applications where reliability and durability are essential.