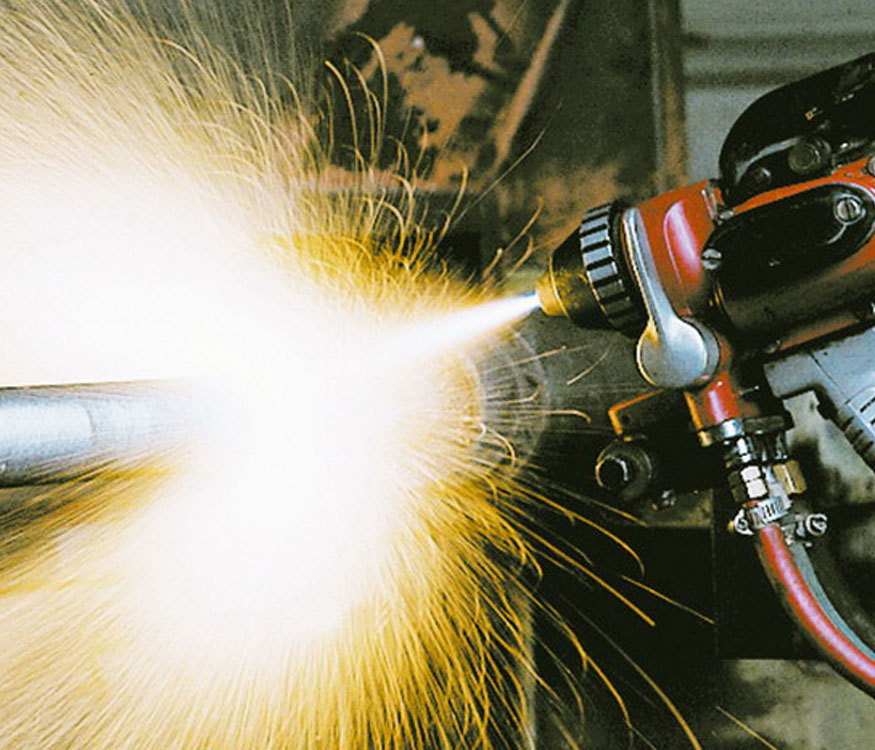

Thermal Spray SS Coating is a highly effective protective layer that enhances the durability and resistance of components exposed to high wear and corrosion. This coating process applies a fine layer of stainless steel to various industrial parts, providing exceptional protection against thermal, mechanical, and chemical stress.

Ideal for parts in industries like aerospace, automotive, and manufacturing, thermal spray SS coating ensures optimal performance and extended service life. By improving corrosion resistance, reducing friction, and offering excellent heat protection, it helps maintain the integrity and reliability of machinery and equipment in demanding operational environments.

Thermal Spray SS Coating provides superior wear, corrosion, and heat resistance. Applied to industrial components, it improves performance, extends service life, and ensures reliable function in high-stress environments.

Thermal Spray SS Coating enhances component durability by providing a protective stainless steel layer. This minimizes wear and corrosion, improving the longevity and reducing the need for frequent repairs, resulting in cost savings and greater operational efficiency.

The coating offers excellent corrosion resistance, protecting parts from harsh chemicals, moisture, and environmental exposure. It ensures components maintain their functionality, reducing the risk of degradation and increasing service life, especially in industries dealing with aggressive environments.

Thermal Spray SS Coating improves high-temperature protection, making components more heat-resistant. This is crucial for machinery operating at elevated temperatures, ensuring they maintain peak performance and extend the lifespan of parts exposed to thermal stress.