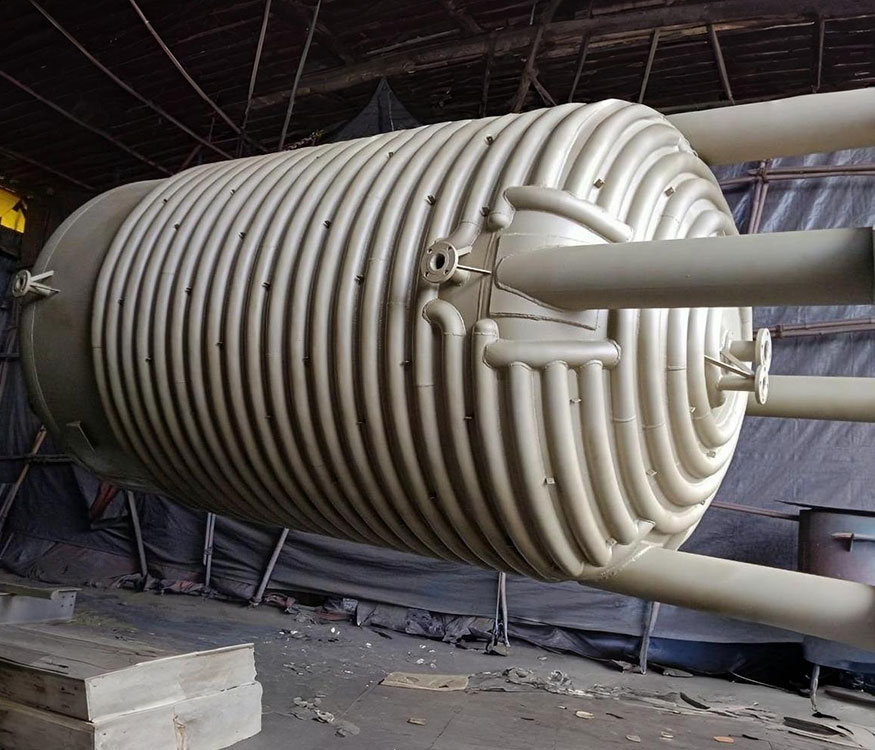

Limpet coil shell ends are designed to optimize heat transfer for reactors and pressure vessels. These coils are welded onto the shell end of vessels, ensuring efficient and controlled heating or cooling of liquids and gases. They improve process stability by maintaining the desired temperature for complex operations.

Widely used in industries such as petrochemicals, pharmaceuticals, and food, limpet coil shell ends provide versatility in temperature regulation. Their robust construction allows for easy integration into pressure systems while maintaining durability and high performance under varied operational conditions, ensuring long-term efficiency in thermal management.

Limpet coil shell ends provide effective thermal regulation for vessels, ensuring uniform heating or cooling. Ideal for industrial processes, they enhance energy efficiency and improve overall system performance.

Limpet coils improve thermal efficiency by facilitating uniform heat distribution through the shell end, ensuring consistent temperature regulation, which leads to higher productivity and energy savings in industrial processes.

Limpet coil shell ends are suitable for multiple sectors like pharmaceuticals, food, and petrochemical industries, where precise thermal management and high-quality product standards are essential for success and compliance.

These coils are designed to withstand high-pressure and temperature conditions, ensuring long-lasting performance. Their corrosion-resistant properties make them reliable in demanding operational environments, reducing maintenance costs and downtime.